This Was Brand New. Broke My Heart.

Share

Watch the Video Here

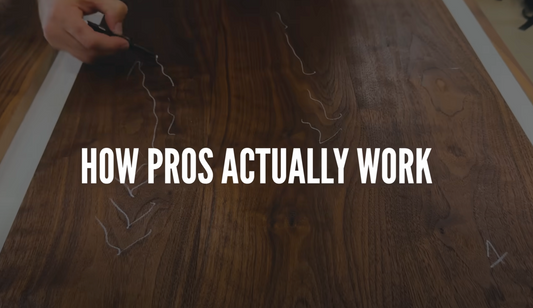

I never thought I’d be writing this about my dream table saw—a three-horsepower, 220-volt SawStop—but after a water leak left it covered in rust, I was forced into one of the most frustrating (and humbling) restoration projects I’ve ever tackled.

Just six months earlier, it was pristine. Brand new. Perfect. Then one day, I walked into the shop and saw the damage. My heart sank. The cast iron surface was splotchy, orange, and rough to the touch.

Trying to Save a $6,000 Saw

I knew I had to act fast. I started with reconditioning oil and a few different abrasive pads. I’d used WD-40 in the past for rust issues, but this time I noticed the reconditioning oil worked better—especially on the tougher spots that wouldn’t budge.

As I worked my way across the surface, I learned the hard way to keep cleaning the pad on scrap wood in between passes. Otherwise, I was just dragging rust particles back and forth. A small tip, but it made a big difference in the results.

When Elbow Grease Isn’t Enough

Despite hours of work, some stains wouldn’t come out. That’s when I broke out the 120-grit sandpaper to go all the way down to the bare metal. It wasn’t ideal—I didn’t want to overdo it—but it was either that or live with a permanently damaged surface.

To fix everything properly, I even had to remove the wooden extension wing, which had warped from the moisture. Pulling apart a machine I’d waited years to own was gut-wrenching, but I knew it was the only way to give it a proper second chance.

A Protective Finish That Actually Works

After getting the surface as clean and smooth as possible, I applied a carbon coat to prevent future rust. It’s not just a gimmick—when applied correctly, it adds a slick, protective layer. I made sure to cover every inch and was honestly shocked by how much it improved the look of the saw. The remaining stains were barely noticeable.

Lessons Learned from the Worst-Case Scenario

This whole experience taught me a lot—not just about rust removal, but about protecting your tools before things go wrong. If you’ve ever dealt with rust or water damage, you know the feeling. But trust me, with patience, the right products, and a little know-how, it’s possible to save even a top-tier tool from the scrap pile.

If you’re facing a similar mess in your shop, I hope this gives you a solid plan of attack—and maybe a bit of hope. I didn’t expect to save this saw. But I did. And I won’t let it happen again.

💵 I can save you 10% if you use the code "WITTWORKS" at the affiliate links below 👇

Carbon Coat Quick Kit: http://t.ly/lZvUK

Reconditioning Oil: http://t.ly/NFSMN

Abrasive Pads: http://t.ly/D5EuV

Carbon Coat Quick Kit: http://t.ly/lZvUK

Reconditioning Oil: http://t.ly/NFSMN

Abrasive Pads: http://t.ly/D5EuV